When it comes to commercial roofing, durability, cost-efficiency, and ease of installation are top priorities. One popular option that meets all these requirements is the Pro-Rib metal roofing system. Commonly used in commercial, agricultural, and industrial applications, a Pro-Rib metal roof provides a practical and long-lasting roofing solution for a wide range of structures. If your building is in Holmen, WI and you are considering pro rib metal roofing call the experts at Golden Eagle Roofing on (608) 633-6719.

What is a Pro-Rib® Metal Roof?

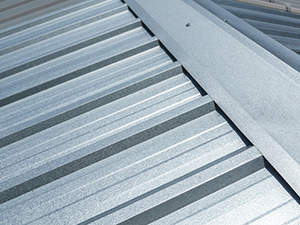

Pro-Rib is a type of corrugated steel roofing panel that features a ribbed design. Each panel typically has raised ribs spaced every nine inches, providing structural strength and a distinctive appearance. These panels are often made from 29-gauge galvanized steel, though heavier gauges are also available for higher durability needs. They are coated with protective layers—such as Galvalume® or painted finishes—to resist rust, corrosion, and fading.

Key Features

One of the standout characteristics of Pro-Rib panels is their easy installation. These panels are designed with an overlapping edge system that allows for a quick and secure fit. For commercial applications, this can reduce labor costs and project time.

Another benefit is their versatility. Pro-Rib metal roofing is available in a wide range of colors and finishes, making it suitable not only for warehouses and industrial buildings but also for retail spaces, office structures, and agricultural facilities.

Additionally, Pro-Rib panels are weather-resistant. The metal material and ribbed design allow for effective water runoff and snow shedding. Many systems also meet or exceed UL 2218 Class 4 impact resistance and Class A fire ratings, which is especially important for commercial safety codes and insurance requirements.

Benefits for Commercial Use

Durability: With lifespans of 40 to 60 years or more, Pro-Rib metal roofs outlast many traditional roofing systems like asphalt shingles or modified bitumen.

Low Maintenance: Once installed, these roofs require minimal upkeep. Occasional inspections and basic cleaning are usually sufficient to maintain their performance.

Energy Efficiency: Pro-Rib roofs can be treated with cool roof coatings that reflect sunlight, reducing cooling costs in commercial buildings.

Cost-Effective: While the initial cost may be higher than some other materials, the long lifespan and minimal maintenance needs make Pro-Rib a smart investment over time.

Installation and Considerations

Commercial Pro-Rib roofing can be installed over existing roofing in some cases, which minimizes the need for tear-off and disposal. However, proper underlayment, fastening systems, and insulation are essential to ensure performance and prevent leaks or condensation.

Hiring experienced metal roof installers is highly recommended, especially for large-scale commercial projects. Proper sealing at seams, flashing around vents and edges, and secure attachment to the building structure are critical steps.

Pro Rib Metal Roof Experts

Commercial Pro-Rib metal roofs offer a blend of strength, efficiency, and affordability that makes them a preferred choice for many business owners and builders. With superior weather resistance, long-term performance, and aesthetic flexibility, Pro-Rib panels provide a dependable roofing solution for any commercial setting. If you are interested in pro rib metal roof in Holmen, WI contact Golden Eagle Roofing on (608) 633-6719.

FAQ

How long does a Pro-Rib metal roof last?

With proper installation and minimal maintenance, Pro-Rib metal roofs can last 40–60 years or more.

Are Pro-Rib roofs energy efficient?

Yes. When paired with reflective coatings or proper insulation, Pro-Rib roofs can significantly reduce cooling costs in commercial buildings.

Can a Pro-Rib roof be installed over an existing roof?

In many cases, yes. However, a professional inspection is needed to confirm if the underlying structure can support the additional weight.

Is Pro Rib metal roof suitable for harsh weather conditions?

Absolutely. These panels are designed to resist wind, hail, snow, and rain, and are rated for fire and impact resistance.

What gauge is typically used for commercial applications?

The most common is 29-gauge steel, but 26-gauge is recommended for higher durability in heavy-duty environments.