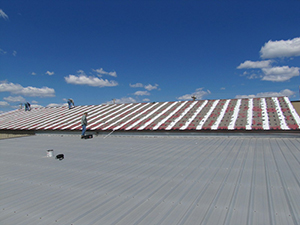

When it comes to choosing a reliable, long-lasting roofing system for commercial buildings in Eau Claire, WI, Pro Rib metal roof systems continue to be a popular and practical choice. Known for their strength, versatility, and cost-effectiveness, these roofs are engineered to stand up to Wisconsin’s harsh winters, heavy snow loads, and seasonal wind gusts.

But beyond their durability and aesthetics, one of the most overlooked yet vital elements of Pro Rib metal roof performance are the rib height and panel width. These two structural features play a major role in how the roof functions under pressure, manages water flow, and withstands the test of time.

If you’re considering a Pro Rib metal roof for your commercial property in Eau Claire, WI, contact Golden Eagle Roofing at (608) 633-6719 to discuss your options and learn what rib specs are right for your building.

Understanding Pro Rib Metal Roofing

Pro-Rib metal panels are typically made of 29-gauge steel and designed with exposed fasteners. These roofs are a staple in both agricultural and commercial construction across the Midwest due to their affordability, ease of installation, and ability to cover large surface areas quickly.

Each Pro-Rib panel has repeating ridges (ribs) that run vertically down its length. These ribs aren’t just for show; they serve as structural reinforcements and play a critical role in:

- Water shedding

- Load distribution

- Fastener alignment

- Expansion and contraction control

Two key measurements determine how a Pro-Rib panel performs:

- Rib Height: Typically ranges from 3/4″ to 1-1/4″

- Panel Width: Usually, 36″ but can vary depending on manufacturer

Why Rib Height Matters in Harsh Climates

Rib height might seem like a minor detail, but in a climate like Eau Claire, WI, where buildings must endure heavy snow and rain, it’s absolutely essential.

Water Drainage and Snow Shedding

Taller ribs create more defined channels for water and melting snow to escape the roof. This reduces the chance of ponding or ice dam formation, two conditions that can lead to leaks or structural strain.

For commercial buildings with low-slope or shallow-pitch roofs, a taller rib height (around 1-1/4″) is usually preferred. It ensures better drainage over wider spans and minimizes the risk of water infiltration during snow melts or rainstorms.

Increased Load-Bearing Strength

The rib acts like a beam, adding rigidity and resistance to deflection. Taller ribs increase the panel’s capacity to bear snow loads without sagging. This is crucial in Eau Claire, where snow accumulation can be both sudden and substantial.

Thermal Expansion Control

Metal roofs expand and contract with temperature shifts. Ribs help manage this movement. A higher rib profile can absorb more movement while maintaining the panel’s shape and secure attachment to the substrate.

Panel Width and Structural Performance

Just as important as rib height is panel width. While most Pro-Rib systems feature a 36” width, not all panels are created equal. The width can influence installation time, aesthetics, fastener alignment, and overall durability.

Fastening and Wind Resistance

Wider panels mean fewer seams and quicker installation, but they can be more vulnerable to uplift in high-wind scenarios unless properly anchored. For regions in Wisconsin subject to strong gusts, especially on open lots or rural commercial properties, extra attention to fastening patterns and clip systems is needed.

A narrower panel with more ribs per square foot can distribute force more evenly and resist movement better under extreme wind stress.

Structural Purlin Spacing

Panel width must be coordinated with the spacing of your building’s structural supports (purlins or joists). Wider panels may require closer purlin spacing for adequate support, affecting framing costs and design.

Golden Eagle Roofing often works with commercial clients in Eau Claire, WI, to evaluate the best width-to-rib ratio for their unique building structure and weather exposure.

Thermal Bridging and Efficiency

Wider panels with fewer ribs may transmit more heat through the metal. Narrower panels with taller ribs can create more air channels, improve insulation efficiency when combined with underlayments or reflective barriers.

Pro Rib Metal Roof Experts

Selecting a Pro Rib metal roof is about more than just choosing steel over shingles; it’s about engineering your roof to perform. Rib height and panel width are more than technical specs; they determine how well your roof will stand up to Eau Claire’s winter loads, summer heat, and year-round precipitation.

By understanding how these features work together, commercial property owners can ensure their investment delivers maximum durability, minimal maintenance, and long-term energy savings.

If you’re in Eau Claire, WI, and want to ensure your building is fitted with a Pro Rib metal roof built to perform under pressure, contact Golden Eagle Roofing at (608) 633-6719 today for a customized consultation.

FAQ

What’s the standard rib height for Pro-Rib metal panels?

Most Pro-Rib panels have rib heights between 3/4″ and 1-1/4″, with taller ribs offering better drainage and strength—ideal for commercial buildings in snowy regions.

How long does a Pro Rib metal roof last?

A: With proper installation and minimal maintenance, Pro Rib metal roofs can last 40–50 years, especially when exposed fasteners are monitored and replaced as needed.

Are Pro-Rib roofs energy-efficient for commercial buildings?

Yes. They can reflect solar radiation, especially in lighter colors, and when combined with insulation or reflective underlayments, they contribute to lower cooling costs.